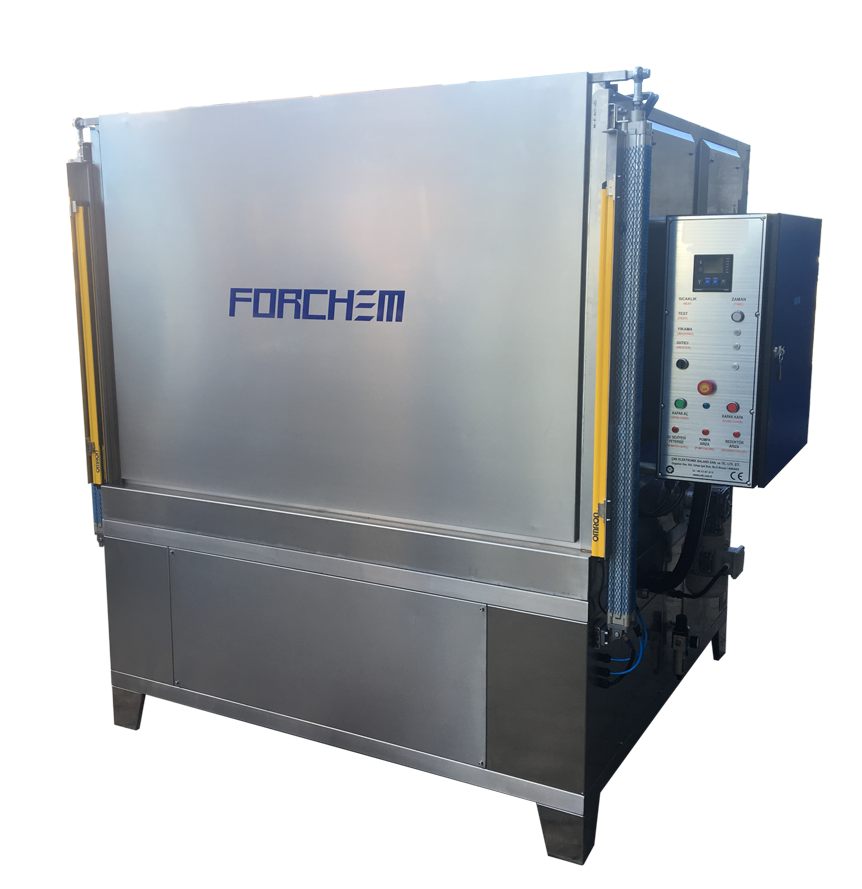

Industrial washing machine for big parts KM 1650

How it works:

Washing is carried out in a fully insulated chamber. The entire wash cycle is performed fully automatically and thus without any manual intervention by the operator of the appliance. During the washing process, the cleaning solution penetrates all parts of the contaminated object using specially positioned nozzles. The solution is fed from the tank using a stainless steel pump. The rotating basket rotates 360° to enhance the washing effect from all sides. In this type of machine, washing and drying is carried out in the same chamber. Depending on the required process, all parameters can be controlled by PLC.

Fields of application:

- Especially in the hydraulic industry, which requires washing according to ISO 4406

- Automobile industry

- Armament industry

- Metalworking industry

Standard features:

- Made of AISI -304 stainless steel

- Stainless steel tank AISI-304K

- AISI -304 stainless steel pump

- Electric resistance heater

- PLC control

- Basket positioner

- Washing temperature settings

- Washing time settings

- Tank level protection against overflow

- Infrared Hand Protection (Optical Gate)

- Two phase filtration

- Pneumatic piston door

- Automatic washing cycle

- Emergency stop button

Additional accessories:

- Oil separator

- Automatic tank emptying

- Digital indicator

- Precise filtration

- Drying module

- Application for washing with acidic products

- Extraction of steam

- Automatic tank filling

VIDEO DEMO

|

TECHNICAL DATA OF KM 1650 |

||

|

Washing basket diameter |

mm |

1500 |

|

Max. height of the object to be washed |

mm |

850 |

|

Max. weight of the object to be washed |

kg |

1000 |

|

Tank capacity |

L |

350 |

|

Time of washing |

min. |

0-60 |

|

Max. temperature of washing |

°C |

85 |

|

Pump power |

kW |

4,4 |

|

Heating power |

kW |

16 |

|

Washing arms |

pcs |

2 |

|

Voltage |

V-Hz |

380-50 |

|

Total power |

kW |

21 |

Photogallery of Industrial washing machine for big parts KM 1650